Call : 07313726541

Call : 07313726541

H.S. COIR INDUSTRIES

GST : 06BEBPS8372H1Z6

GST : 06BEBPS8372H1Z6

We provide complete end-to-end solution for Coir Mattress Making Machine, Industrial Continuous Foam Machine, EPE Foam Roll Cutting Machine, etc.

- New Arrivals

- Featured

About H.S. Coir Industries

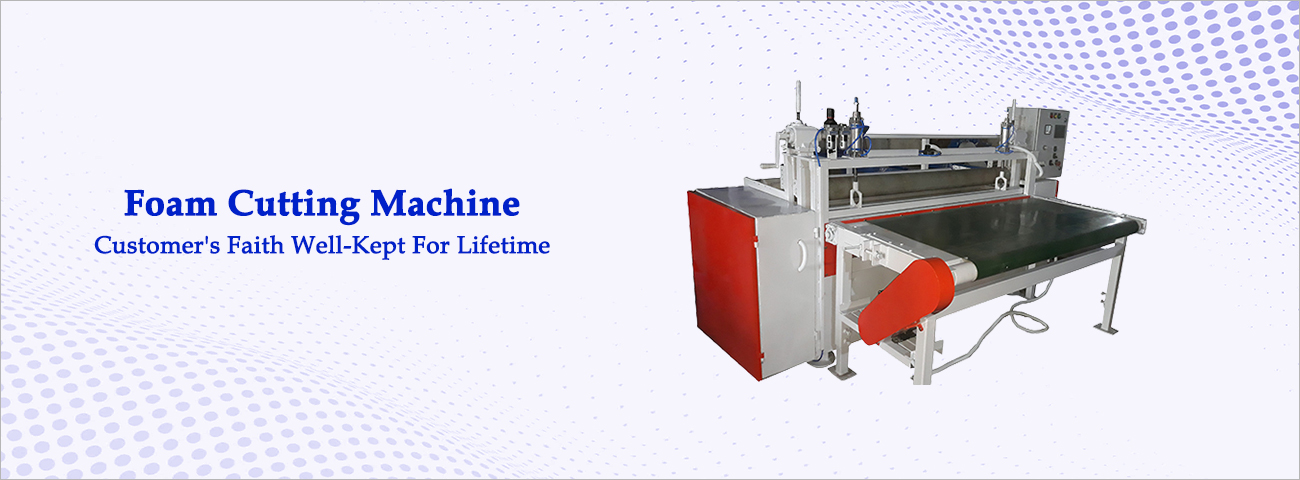

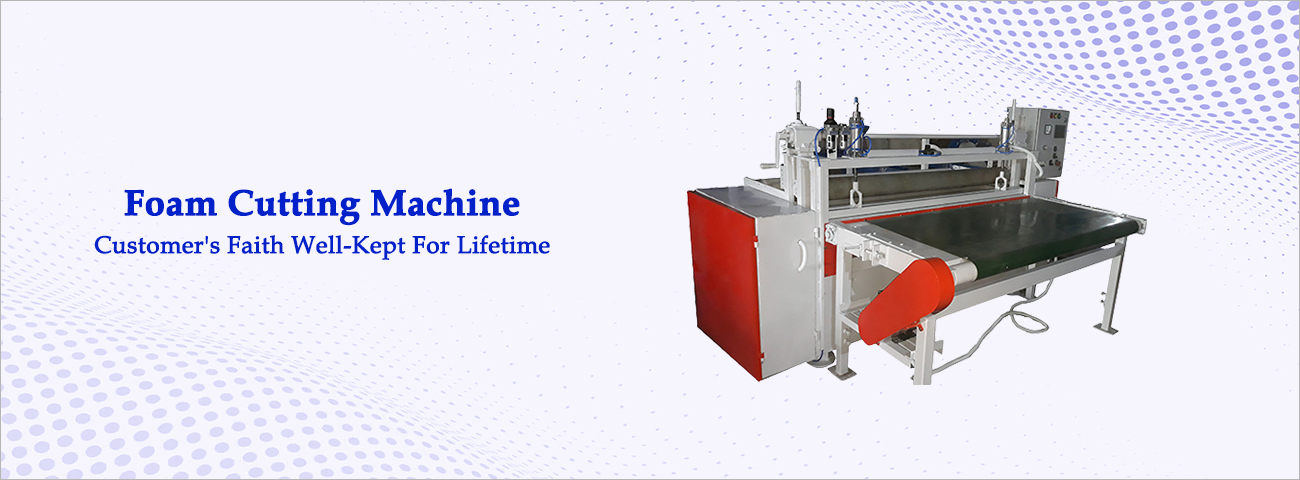

Production factories of goods like pillows, mattresses, etc., of different scales need machines and equipment of various types and in varying capacities. With our strong technical foundation dating back to the year 2003, we apply mature production techniques to construct a durable, efficient and low-cost range of Coir Mattress Making Machine, Fibre Carding Machine, Foam Cutting Machine, Pillow Making Machine, Foaming Plant And Machine, etc. Our innovative foam cutting machines can be used while creating both foam and coir mattresses of different sizes.

As an original manufacturer of high-tech machines used in different industrial and agricultural works, we follow advanced production technology. We have special technology machines that can be utilized for making quality coir mattresses in minimal time. We act as a one stop shop of machines, each designed for specific works. In fact, we have many innovative machines to de-fiber coir, sturdy Pith machines to flawlessly cuts fiber and then load heavy volumes of husk chips with less effort.

Use of latest trends technology is also seen in the way we strictly make use of A-grade raw materials and the most sophisticated interlocking technology of sheets during product engineering. Besides, a thorough quality check done following international standards and norms on all the machines helps us assure delivery of a range that gives specific results in an accurate and affordable way. Internal testing of our range on a plethora of parameters ensures each of the machines functions optimally without requiring maintenance for years.

Our Motto

We continually improve our production processes as a Coir Machine manufacturer and PU Foaming Machine manufacturer, and elevate the standards of our team to make sure we keep pace with our motto of providing clients with functional, robust and competitively priced Coir Mattress Making Machine, Fibre Carding Machine, Foam Cutting Machine, Pillow Making Machine, Foaming Plant And Machine, etc. Our machine range is widely demanded in industry verticals engaged in undertaking various manufacturing works of automotive seat cushion, carpet cushions, mattress padding, upholstered furniture cushions, etc., also because of the following traits:

- Compact frames

- User friendliness

- Work consistency

- Low operation expenses

- Ability to work on bulk quantities of rigid foams and other materials

Our Values

- Collaborate: To use our foresight and collaborate with the right partners who can help us engineer leading-edge machines and equipment as per international technology.

- Innovate: To keep an eye on market technologies and adopt the right ones that can help us design high-accuracy and futuristic machine models at low cost.

Back to top

|

H.S. COIR INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry